1 During July, 2000 I purchased a used set of Unorthodox Racing underdrive pulleys from the same person I had previously bought the Hamann pedal covers. He had a…

2 I received the pulley set and the shortened belts from the 1998 M Roadster a couple of weeks later. Everything looked to be in order.

3 I decided to use Last Minute Racing in Stratford, CT to perform the install. They are a team of BMW's competing in the SCCA SpeedVision World Challenge Series.…

6 The technician on the left verifies that the car is instrumented properly, while Alain Chebeir oversees on the right.

7 The car is strapped down onto the dynomometer by 4 belts. 2 lower belts go straight, and the upper 2 angle in to keep the car from moving. Alain is in the…

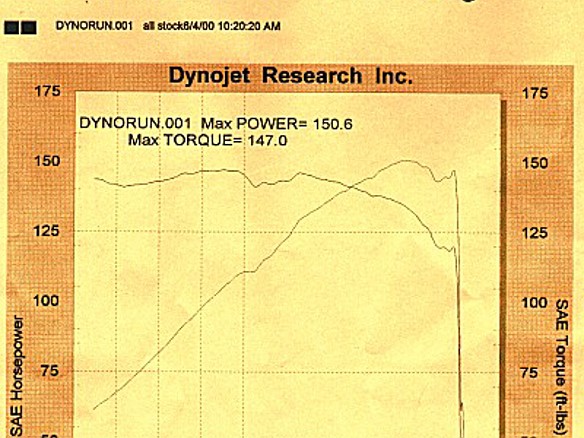

8 Here are the dyno results of my stock 2000 Z3 2.5L roadster done in 3rd gear showing horsepower and torque plotted against RPM. After we unhitched my car from…

9 Back at Last Minute Racing's secret facility, it was now time to begin installing the Unorthodox pulley set... A customer's silver M3 had to be taken off the…

10 Two of Alain Chebeir's techs, removing the factory pulleys from my car. I wish I could remember their names, but they were very thorough and very professional.…

11 With the OEM pulleys removed, installation of the Unorthodox pulleys began. Unfortunately, nothing was lining up properly. The Unorthodox power-steering pulley…

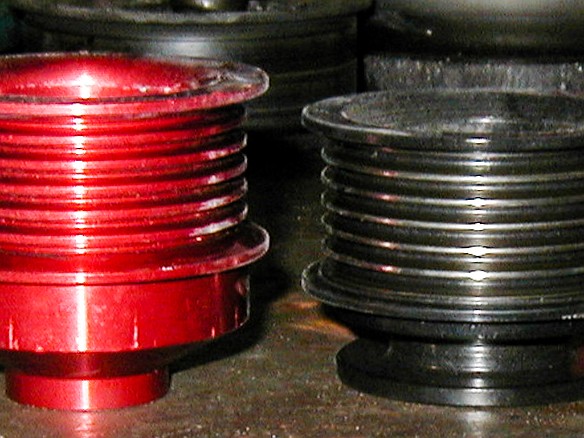

12 The offset incompatibility is obvious between the Unorthodox power-steering pulley on the left, and the OEM pulley from my MY2000 Z3 on the right.